-

-

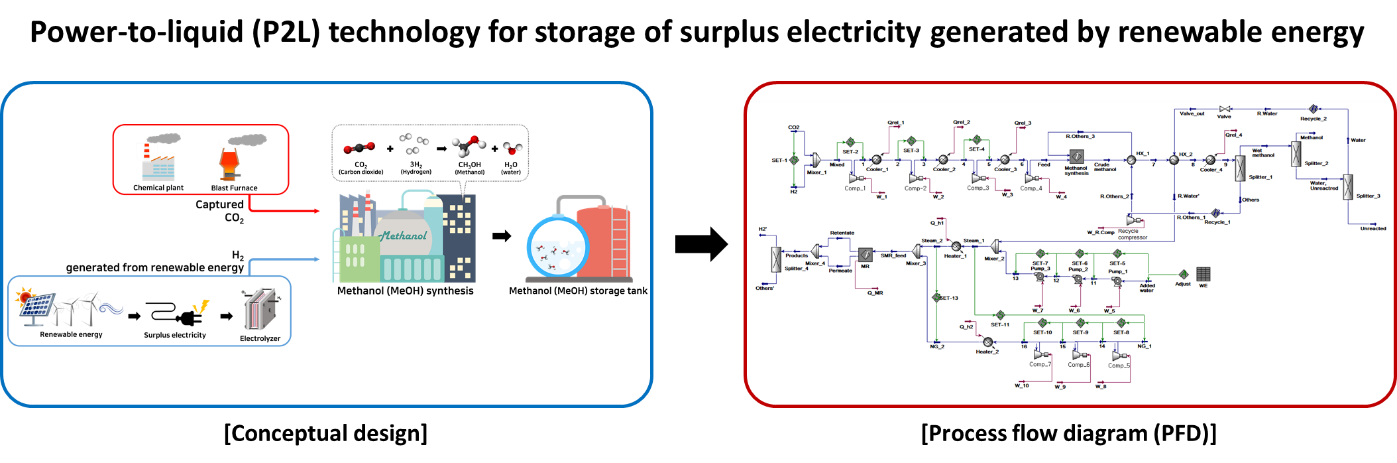

Process Simulation & Design

The aim of process simulation and design is to develop a robust and reliable process model which can be applied to various industrial areas like chemical plants, power plants, biological treatment systems, environmental abatement systems, electrochemical devices, just to name a few. Process simulators can be used for this analysis focusing on material and energy balances related to processes of particular interest.

-

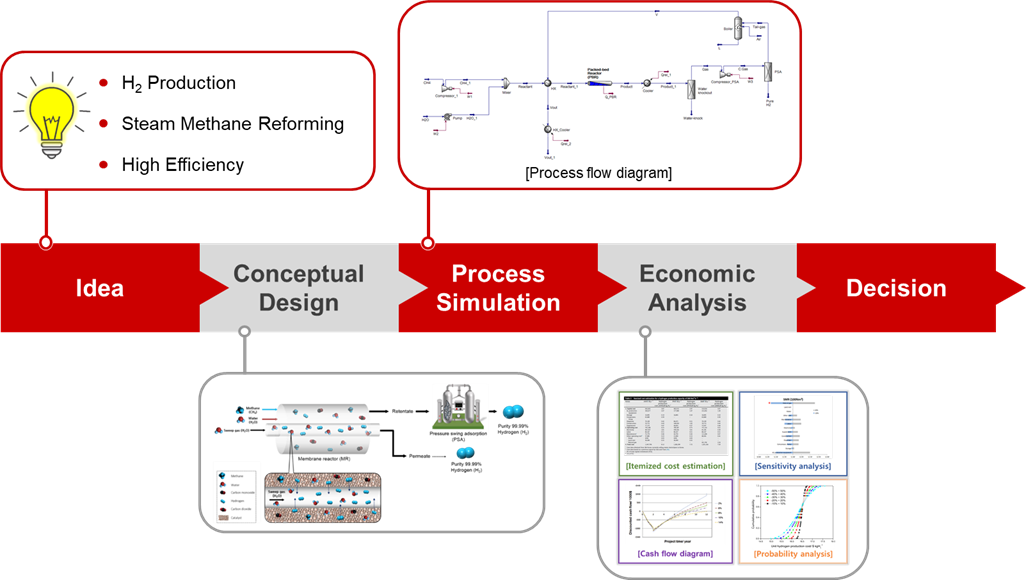

Techno-economic Analysis (TEA)

To assess the technical and economic feasibility of proposed processes, techno-economic analysis (TEA) is required. Based on technical evaluation, various economic analysis methods such as itemized cost estimation, sensitivity analysis, profitability analysis, probability analysis, etc. are used to provide the techno-economic feasibility of the proposed processes.

-

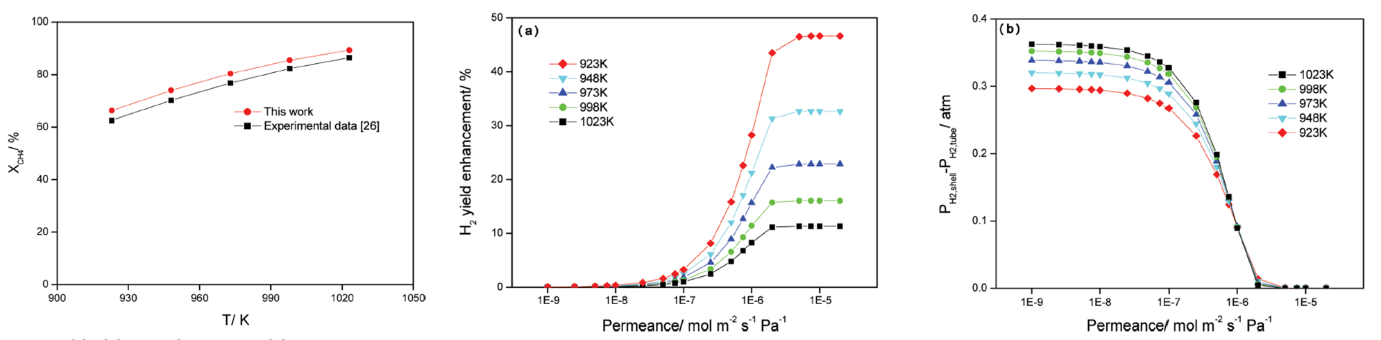

Numerical Modeling

Numerical modeling is to construct governing equations to describe proposed systems and carry out parametric studies to investigate the effect of various operating conditions on the performance in the systems. Numerical analysis tools are employed to analyze the systems and provide useful design guidelines.

-

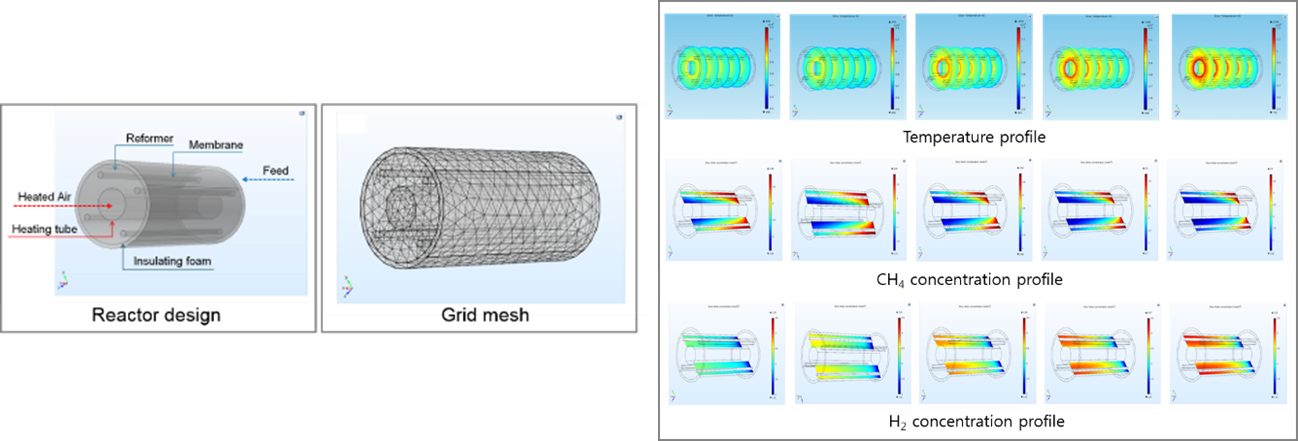

Computational Fluid Dynamics (CFD)

-

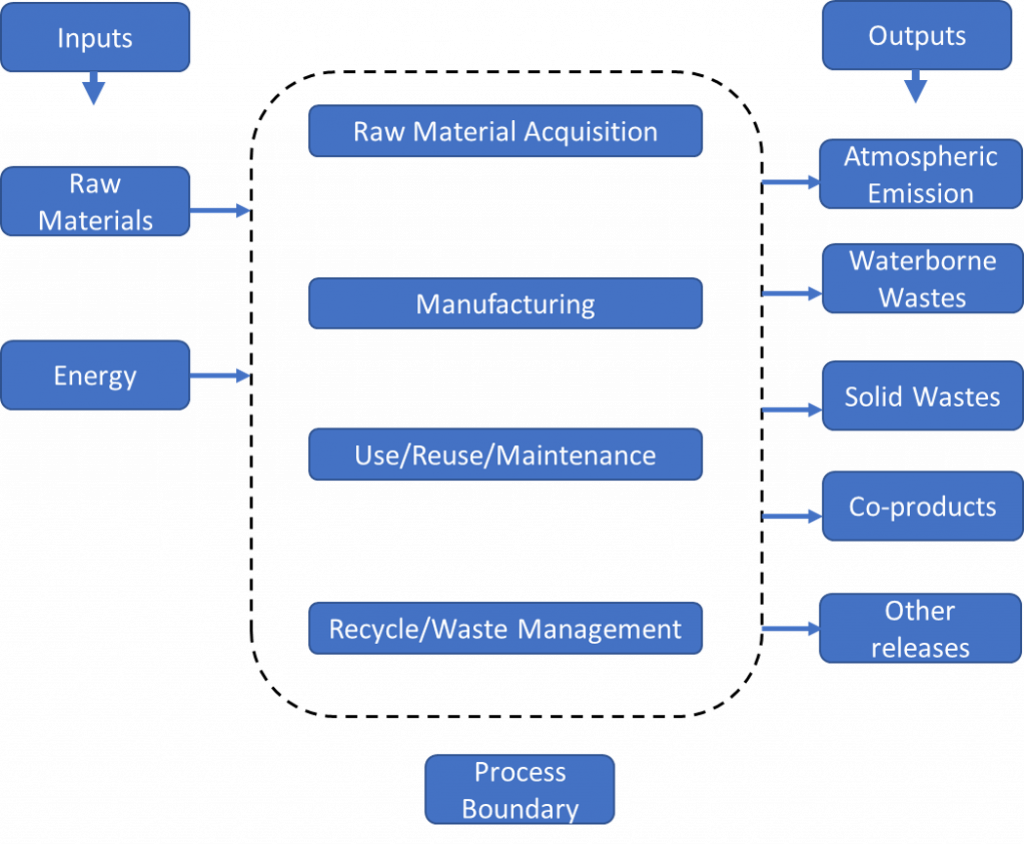

Life Cycle Assessment (LCA)

Basically, LCA is a tool to evaluate the environmental effects of a product or process throughout its entire life cycle. An LCA entails examining the product from the extraction of raw materials for the manufacturing process, through the production and use of the item, to its final disposal, and thus encompassing the entire product system.

-

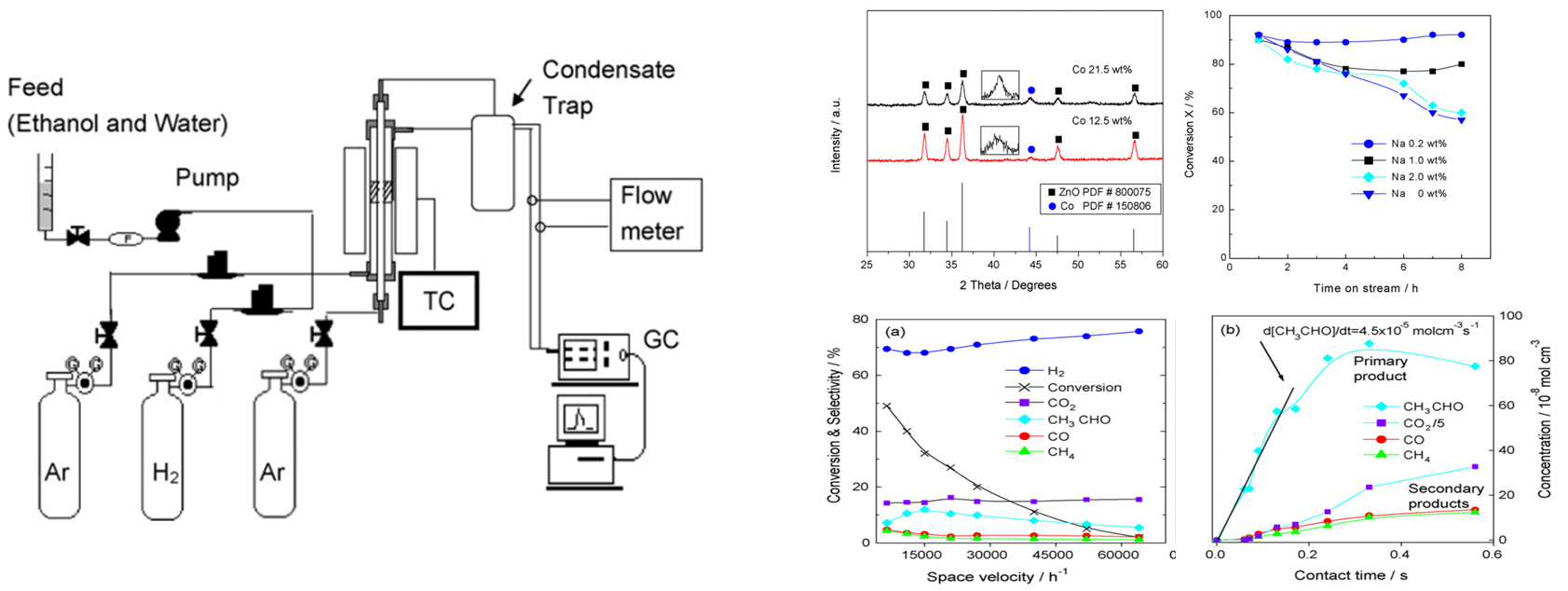

Catalytic Reaction

Catalytic reaction is a crucial element in chemical engineering disciplines covering steam reforming to produce H2, reduction of greenhouse gases, abatement of volatile organic compounds, utilization of CO2 for useful products, etc.. The interests of our group lie in various areas ranging from fundamental studies to obtain reaction kinetics to applied analysis for optimized reactor design.

-

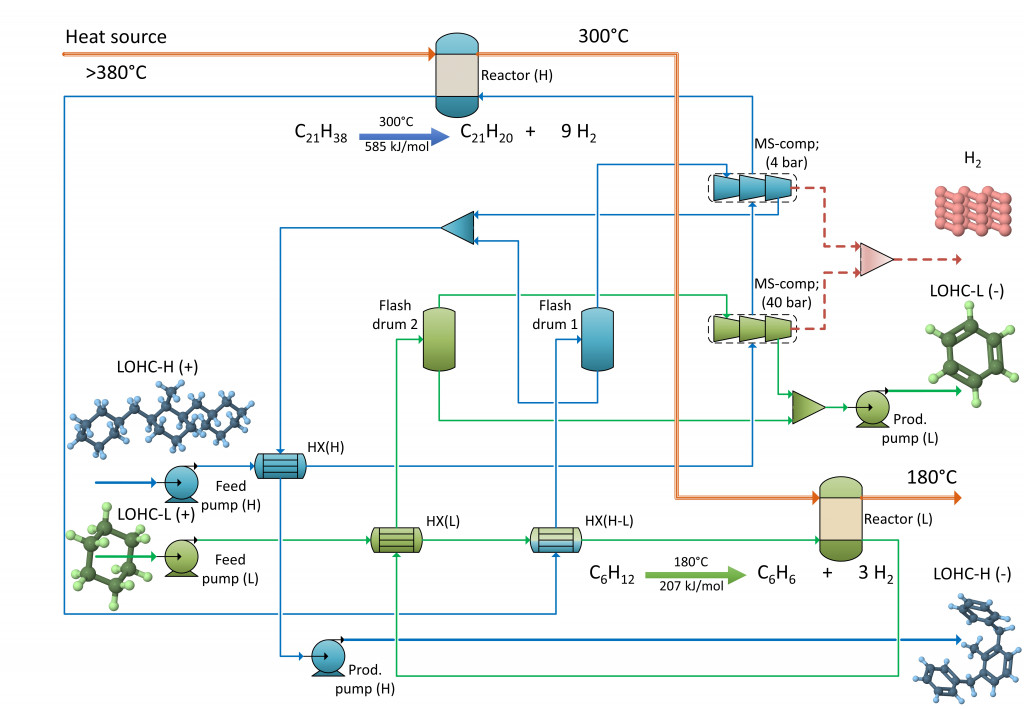

Liquid Organic Hydrogen Carrier (LOHC)

Liquid organic hydrogen carriers (LOHCs) have taken a spotlight as a possible alternative for hydrogen (H2) storage and transportation compared to more conventional methods such as pressurized H2 and liquified H2. In an increasingly alternative energy supply, efficiency of commercial scale H2 release from LOHC systems is paramount for a viable H2 economy.

Liquid organic hydrogen carriers (LOHCs) have taken a spotlight as a possible alternative for hydrogen (H2) storage and transportation compared to more conventional methods such as pressurized H2 and liquified H2. In an increasingly alternative energy supply, efficiency of commercial scale H2 release from LOHC systems is paramount for a viable H2 economy. -

Biomass valorization

Today, various kinds of waste have been occurring anywhere and making serious problems in environments. These waste resources are treated by incineration, landfill, and discharge sea/lake/river. Recycling, especially the challenge of making energy sources or value-added products are always required by effective, economic, and innovative strategies. Our group is looking for various ways to correspond with these challenges. In particular, we are developing various technologies aiming at the implementation of a clean, renewable, and sustainable society through the application as an energy source and environment.

-

-

-

University

-

National Research Institute

-

Private Sector

-

Public Sector

-